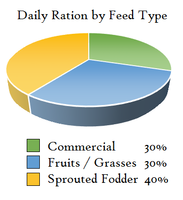

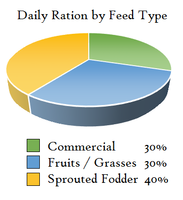

We are at day 7 in our quest to decrease our chickens feed bill; this attempt by sprouting barley. I read that by sprouting the feed you can get a 5:1 increase in feedstock, thereby decreasing the overall cost of daily feed. We are shooting for 30% Commercial feed, 30% Fruits/grasses and 40% Sprouted fodder. The kind of seed we decided on was easy- there are only two types readily available here: Barley and Wheat. I can get just about any seed, but shipping can take up to 6 weeks if they add my order to a bulk load coming over from the mainland. This barley is field run, un-GMO free certified , non-organic or just a plain old bag of seeds and it still is 20$ for a 50 pound bag. But with a 5:1 increase in feed stock, this brings the price down to a reasonable level from .40 cents a pound to about .08 cents a pound.

We got going by buying a 5 shelf wire rack, black plastic growing trays from the local Garden Exchange with drain holes pre-punched, pump for circulating the water and a timer to set the pump times and of course; Barley seed. We have some tweaking to do on the system- the catch tub with the pump is too narrow and some of the rinse water falls to the left and right of the tub. The pressure isn't strong enough to use the spray feature of the emitters we have in the tubing, so we'll be changing the outflow port for more soon. The timer we purchased has a 4 set cycles capability with 20 simultaneous programmed memory. We need the pump to activate for about 4-5 minutes, every 3 hours during the day. When I get this figured out, this timer should do well.

This is the 5 shelf rack we got at the local big box store. The wire shelves allow for drainage and the paint resists rust. Out here, if it's metal, it will rust. How long we can put that off depends on paint, powdercoats, oiling etc. But they will rust. I plan on adding a set of accessory shelves to these and narrow them to get more trays- if we bump up the percentage of fodder to double or 80% of their rations, we can decrease the commercial feed accordingly.

This photo is the various stages of the sprouting. The raisin looking things in the second shelf, first tray is lava cinder. I dropped the tray and tried to separate it best I could. Better I guess to heave the lot when this happens, but as it takes a 24 hour soak for the seeds prior to traying them, it would put a space in the feeding routine. Since this was a first weeks worth, I tried saving it- but next time, I'll just double up on the seed in the next soak and spread two trays to "catch up" in the cycle.

This photo is the various stages of the sprouting. The raisin looking things in the second shelf, first tray is lava cinder. I dropped the tray and tried to separate it best I could. Better I guess to heave the lot when this happens, but as it takes a 24 hour soak for the seeds prior to traying them, it would put a space in the feeding routine. Since this was a first weeks worth, I tried saving it- but next time, I'll just double up on the seed in the next soak and spread two trays to "catch up" in the cycle.

This photo is showing the distribution tubing and emitters zip tied into place. This will change as the need for the shelf presents itself. They drip fine, they just don't spray like they are supposed to. The pump is supposed to put out 500 GPH, plenty for a spray but I have the tubing plugged into the accessory port rather than the 'fountain' port where most of the pressure diverts to.

This photo shows the tub and pump, though the hazy rinse water keeps you from seeing the pump itself. The haze is from the dirt, dust and barley fines that happen in shipping and is half carbohydrate half dirt. The first rinse and soak water is discarded. This is just the watering cycle and comes from the water in the first trays dripping down to the second shelf, to the third, etc, until it gets back to the sump. If this water is not changed every three days, it starts to ferment and smell. As it is, the moist barley attracts the fruit flies that attract the geckos, that attract the birds that forget about the geckos because of all the seed! A minor problem overall if the cost savings play out as suggested on the internet sites touting this method.

This photo shows the tub and pump, though the hazy rinse water keeps you from seeing the pump itself. The haze is from the dirt, dust and barley fines that happen in shipping and is half carbohydrate half dirt. The first rinse and soak water is discarded. This is just the watering cycle and comes from the water in the first trays dripping down to the second shelf, to the third, etc, until it gets back to the sump. If this water is not changed every three days, it starts to ferment and smell. As it is, the moist barley attracts the fruit flies that attract the geckos, that attract the birds that forget about the geckos because of all the seed! A minor problem overall if the cost savings play out as suggested on the internet sites touting this method.

I will update as I go along- I like saving money and I'll share what I learn.

We got going by buying a 5 shelf wire rack, black plastic growing trays from the local Garden Exchange with drain holes pre-punched, pump for circulating the water and a timer to set the pump times and of course; Barley seed. We have some tweaking to do on the system- the catch tub with the pump is too narrow and some of the rinse water falls to the left and right of the tub. The pressure isn't strong enough to use the spray feature of the emitters we have in the tubing, so we'll be changing the outflow port for more soon. The timer we purchased has a 4 set cycles capability with 20 simultaneous programmed memory. We need the pump to activate for about 4-5 minutes, every 3 hours during the day. When I get this figured out, this timer should do well.

This is the 5 shelf rack we got at the local big box store. The wire shelves allow for drainage and the paint resists rust. Out here, if it's metal, it will rust. How long we can put that off depends on paint, powdercoats, oiling etc. But they will rust. I plan on adding a set of accessory shelves to these and narrow them to get more trays- if we bump up the percentage of fodder to double or 80% of their rations, we can decrease the commercial feed accordingly.

This photo is showing the distribution tubing and emitters zip tied into place. This will change as the need for the shelf presents itself. They drip fine, they just don't spray like they are supposed to. The pump is supposed to put out 500 GPH, plenty for a spray but I have the tubing plugged into the accessory port rather than the 'fountain' port where most of the pressure diverts to.

I will update as I go along- I like saving money and I'll share what I learn.

LOL, I get a lot of that but Paradise does have its darker side. We live on the wet side of the island (100-300 inches / year) so it's lush jungle wherever someone has stopped hacking it back and it's a magnificent 85 degrees with 90% Humidity. Everyday. Whether it's January, June, August, December, it's going to be 85 degrees at my altitude. I love it here, but the biggest drawback to living on an Island 3000 miles from anywhere is that we have to ship everything we need in from the mainland, the Asia or from Japan. For example, the barley I stared this sprouting project with cost me 19.75 for a 50 pound sack. I can order a pallet of it to save a bit by buying in bulk, but the pallet will come by boat, not by truck. There are two boats from the US mainland- one takes 3 weeks, the 'fast' boat, and the other that takes 6 weeks, aka the 'slow' boat. The added cost of a bag of seed? $9.75 per bag! I can get it through Lakeland Feed for $9.49 per bag, but they don't ship to Hawaii at all. Heck, even

LOL, I get a lot of that but Paradise does have its darker side. We live on the wet side of the island (100-300 inches / year) so it's lush jungle wherever someone has stopped hacking it back and it's a magnificent 85 degrees with 90% Humidity. Everyday. Whether it's January, June, August, December, it's going to be 85 degrees at my altitude. I love it here, but the biggest drawback to living on an Island 3000 miles from anywhere is that we have to ship everything we need in from the mainland, the Asia or from Japan. For example, the barley I stared this sprouting project with cost me 19.75 for a 50 pound sack. I can order a pallet of it to save a bit by buying in bulk, but the pallet will come by boat, not by truck. There are two boats from the US mainland- one takes 3 weeks, the 'fast' boat, and the other that takes 6 weeks, aka the 'slow' boat. The added cost of a bag of seed? $9.75 per bag! I can get it through Lakeland Feed for $9.49 per bag, but they don't ship to Hawaii at all. Heck, even